At GSPK, embodying a 'can-do' attitude is more than just a mantra; it's the driving force behind our commitment to finding innovative solutions for our clients.

Recently, a customer approached us with a unique challenge. They were encountering difficulties sourcing copper bus bars for a critical power electronics project, struggling to meet the necessary tolerances from their regular supplier. Despite the complexity - with dimensions exceeding our standard manufacturing parameters - our team of engineers took on the challenge head-on.

Utilising our expertise and ingenuity, we embarked on a journey to reimagine conventional manufacturing techniques. Through meticulous planning and resourcefulness, we successfully adapted our processes to accommodate the oversized bus bars, pushing the boundaries of what's possible in PCB manufacturing.

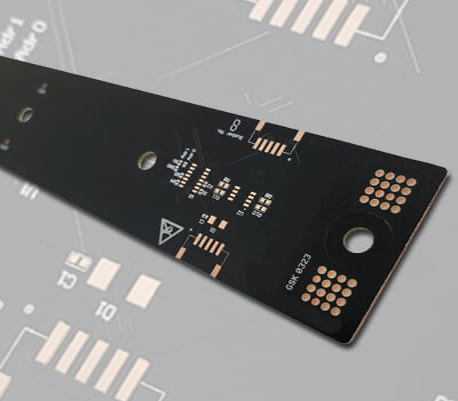

The end result? A triumph of innovation and collaboration. Our custom-manufactured bus bars boast an impressive specification, featuring 640oz of copper and 2.24mm of copper tracking for unparalleled reliability and performance.

But we didn't stop there. Recognising the importance of integration and efficiency, we went a step further by incorporating the customer's temperature sensor board directly within the bus bar itself. This not only streamlined their assembly process but also showcased our dedication to meeting our clients' unique needs with tailor-made solutions.

At GSPK, we thrive on challenges, turning obstacles into opportunities for growth and advancement. This project exemplifies our unwavering commitment to excellence and our relentless pursuit of innovation. From PCB manufacturing to groundbreaking solutions in power electronics, count on GSPK to deliver results that exceed expectations.

Date : 15-05-2024