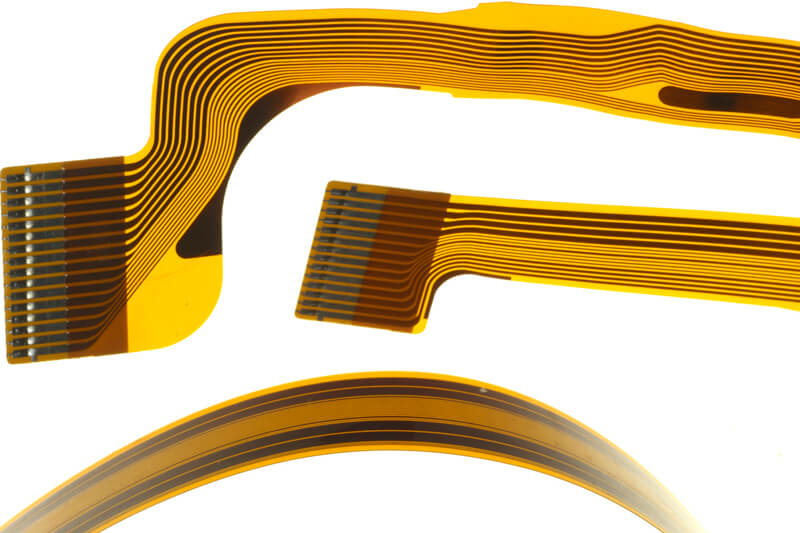

Rigid-Flex and Flex PCBs will all be built with a level of flexibility. A Flex circuit will be completely flexible and a Rigid-Flex circuit will consist of two or more rigid boards connected with a dynamic flexible join.

The ability of these boards to fit into tight spaces when no other solution would work, is often considered as their primary benefit, but they also have a lot of other benefits.

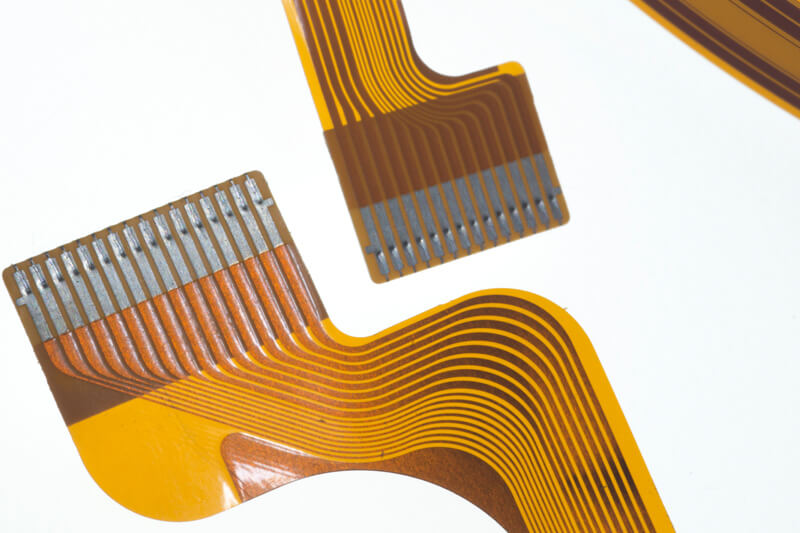

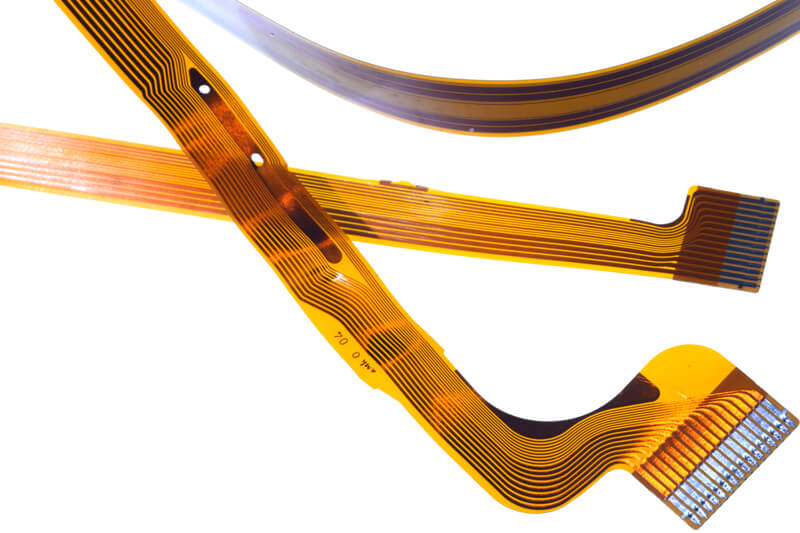

The terms FPC (Flexible Printed Circuit), Flex Circuit Boards, Flex PCBs, Flex Circuits, and Flexible Printed Circuits are also used to describe flexible printed circuits. They consist of a conductor circuit enclosed in a thin coating of insulating polymer. Polyimides are widely used in construction because they allow for high temperature assembly or product environments. Flex circuits can be produced as a connection or with a component-use design. Stiffeners that are rigid may be used. They can be built with one side, two sides, or multi layers.

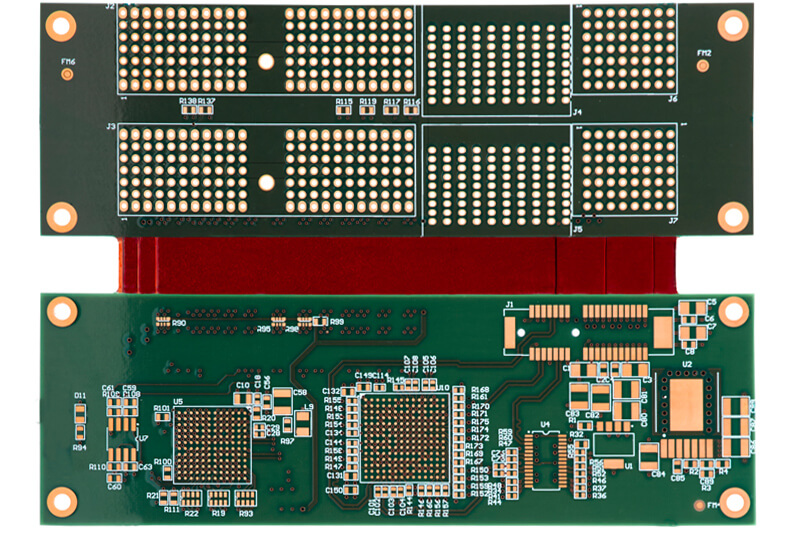

Rigid Flex boards are hybrid boards that, by definition, combine a Flex board with a rigid circuit component. These hybrid circuits can consist of two or more rigids connected by Flex circuits, a Flex with a FR4 stiffener, or both. Rigid Flex circuits combine the best features of rigid boards and flexible circuits onto a single PCB.

Rigid Flex circuits are incredibly adaptable and have a wide range of uses. Designers frequently believe that they are the best option for utilising the packing space that is available.

This technique is also motivated by improved product dependability and overall lower assembly costs.

Advantages include:

| Standard | Advanced | Comment | ||

|---|---|---|---|---|

| FCCL (adhesiveless) | IPC-4203/11 | 25µm, 50µm 75µm | 100um | |

| Copper | 0.5oz(17µm), 1oz (35µm) | 2oz (70µm) | ||

| Coverlay | IPC-4203/1 | Adhesive 25µm, 50µm, 75µm | Colour: Amber | |

| Flex Solder Resist | Green, Amber | |||

| Bo Flow Prepreg | /97/98/99/101/126 | 106 , 1080 | /40 | Other material on request |

| Rigid Laminate | 0.075 - 1.0mm | Other material on request | ||

| Bonded Rigidiser / Stiffener | Coverlay (0.05-0.25mm), FR4 Laminate (0.1-3.2mm), Prepreg | Aluminium | ||

| Outline | Breakaway Tab, Single PCB | |||

| Surface Treatment | HASL, HASL lead free (single-side FPC only), ENIG, OSP (no-stiffener only) | |||

| No. Flex Layers | 2 | 8 | Higher layer count on request | |

| No Rigid Layers | 10 | 14 | ||

| Thickness | 0.2 - 3.2mm | '0.06-5.00 | ||

| Thickness Tolerance (Rigid) | '+/-10% | / | ||

| Thickness Tolerance (Flex) | '+/-0.05mm | '+/-0.03mm | ||

| Minimum Board Size | '15 x 15 mm | '5 x 15 mm | ||

| Max Board Size | '266.7 x 430 mm | 350 x 500 mm | Larger sizes are avaiable on application | |

| Minimum Track / Gap | Inner Layer 17µm | 90µm | 50µm | |

| Inner Layer 35µm | 100µm | 80µm | ||

| Inner Layer 70µm | 200µm | 175µm | ||

| Minimum Track / Gap | External Layer 17µm (base) | 100µm | 75µm | |

| External Layer 35µm (base) | 125µm | 100µm | ||

| External Layer 70µm (base) | 225µm | 200µm | ||

| Minimum BGA pad | 17um base Copper | 250µm | 200µm | |

GSPK will discuss your project and manufacture your Flex and Rigid Flex circuits in the materials and surface finishes that precisely meet your application.