Copper Coin Technology

At GSPK we can offer Copper Coin technology for thermal management in PCBs.

One of the greatest materials for controlling heat while maintaining electrical and/or thermal conductivity is copper with a thermal conductivity of upwards of 400 W/mK.

A copper coin is a solid piece of copper that is put onto or into the PCB, usually beneath the component or components that require cooling. When compared to a collection of thermal vias copper coins will produce roughly twice the cooling.

Additionally, the copper coin can offer direct contact between the heat-generating component pad and the heat sink in place of thermally conductive material. Compared to other conductive dielectric prepregs, copper has thermal conductivity that is typically 50–200 times better.

Regardless of the number of layers in the PCB, copper coins offer the best localised heat transfer solution. The optimal conditions for using this technology are when a single or a small group of PCB components generate most of the heat.

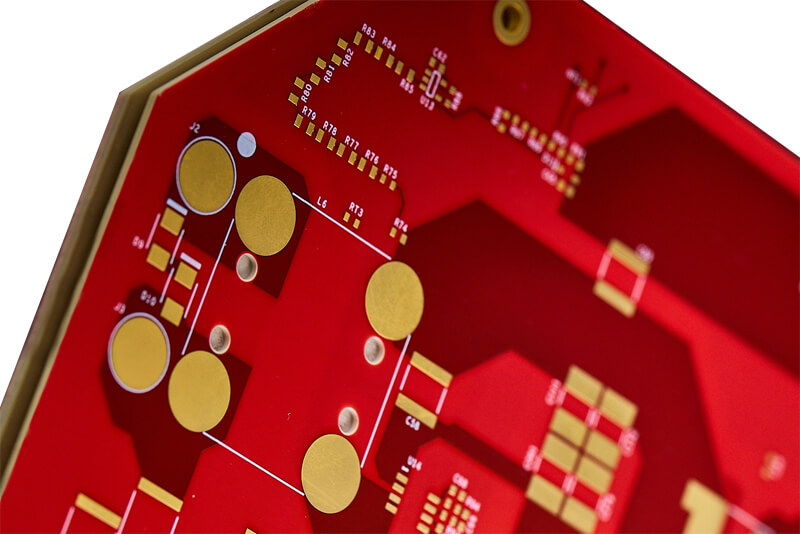

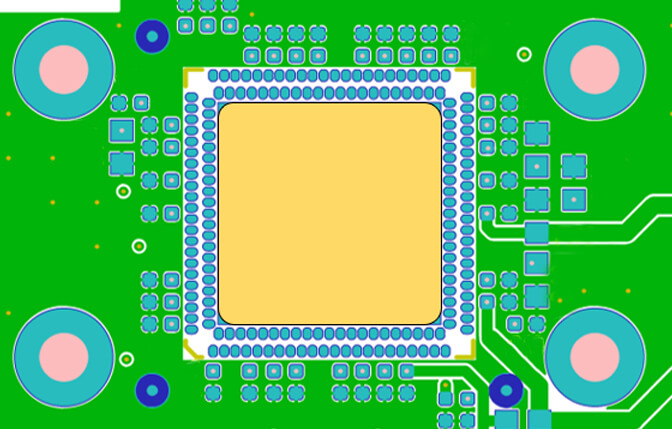

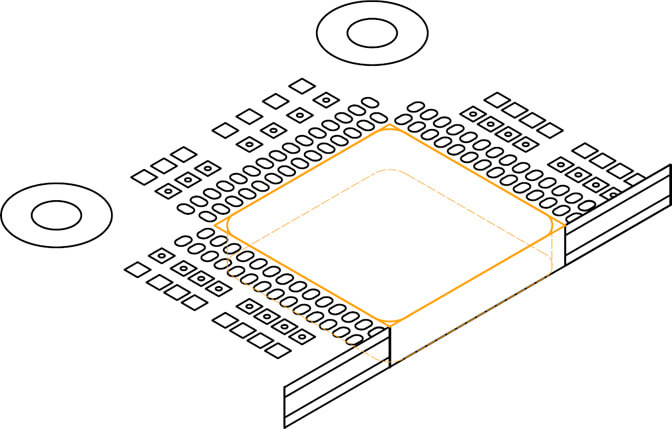

Solid Copper Coin

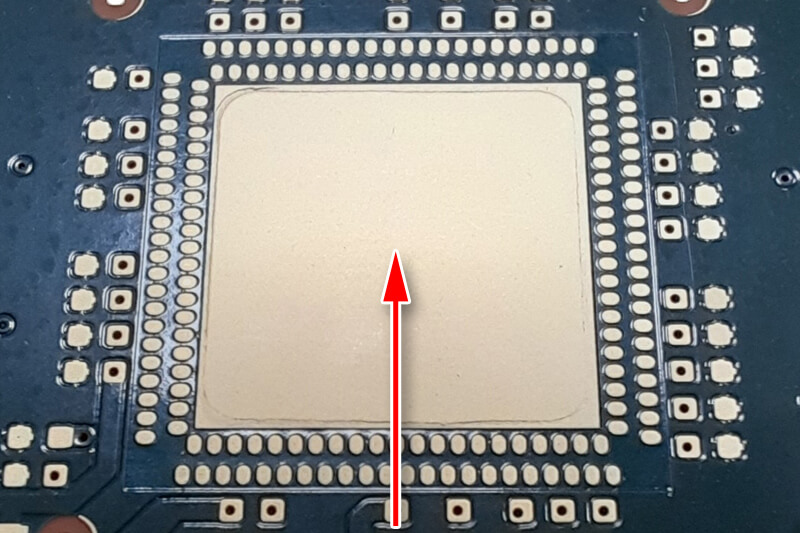

Solid Copper Coin Cross Section of Copper Coin

Cross Section of Copper CoinWhen manufacturing a Copper Coin printed Circuit Board at GSPK Circuits we normally use a solid piece of electrical grade C103 copper bonded directly into the PCB.

Copper coins can be any shape, and you can place one on the top layer and one on the bottom layer, with or without an electrical connection.

The Copper Coin can be bonded through the entire board, leaving it exposed on each side or bonded into the panel from one side only. The Copper Coin is used to dissipate high levels of heat generated by components mounted directly above or below the coin.

Grade C103 copper is used due to its high level of electrical conductivity and low susceptivity to hydrogen embrittlement.

Copper Coin technology can be used in combination with other technologies offered by GSPK such as copper filled vias to provide a solution to the most challenging board designs.

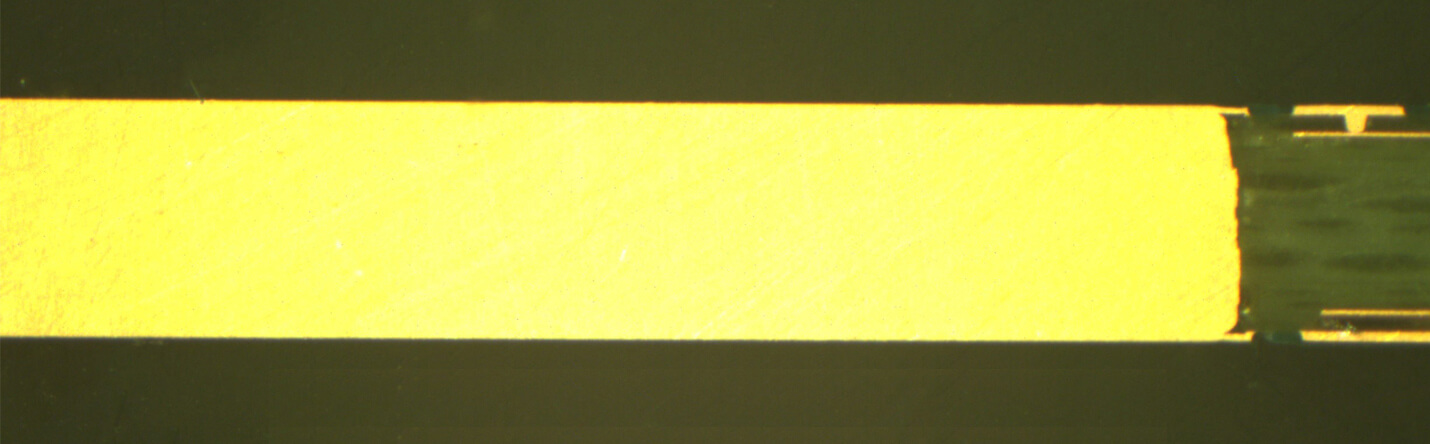

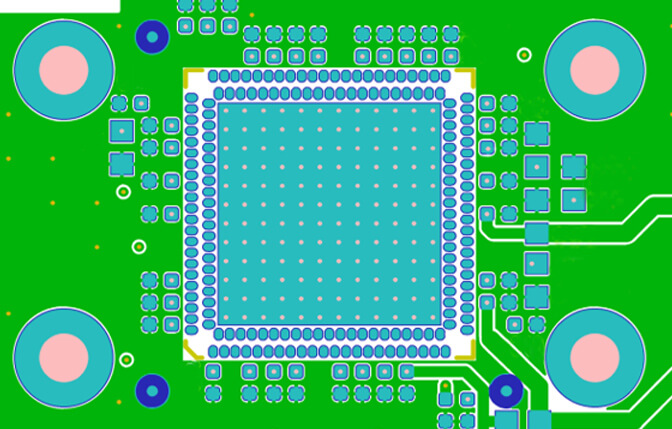

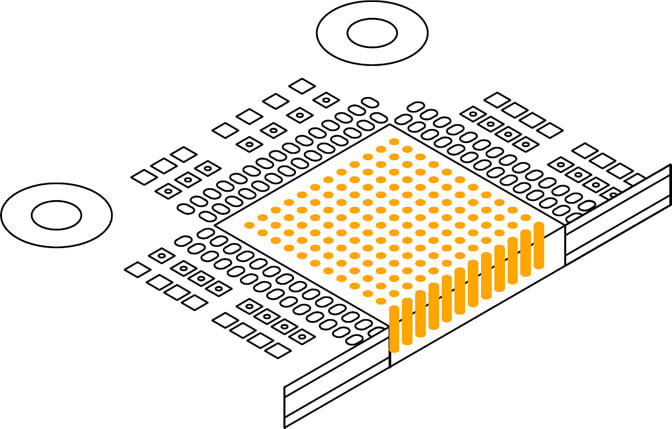

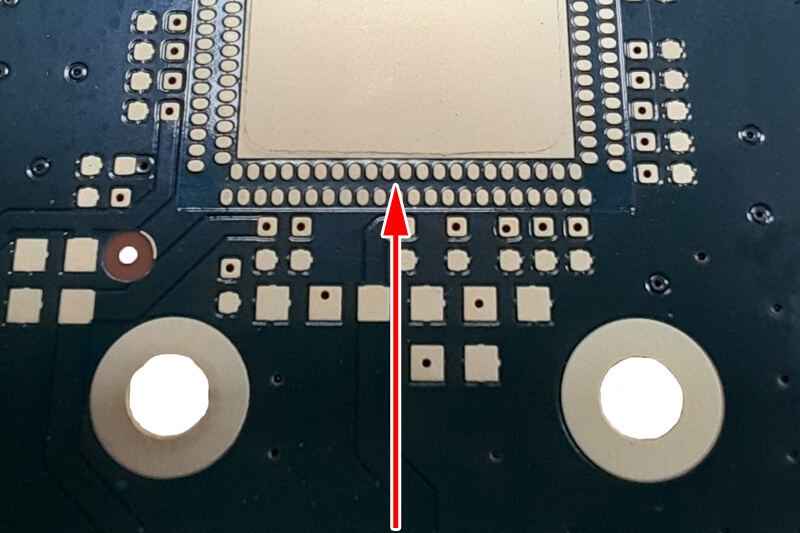

Copper filled blind vias

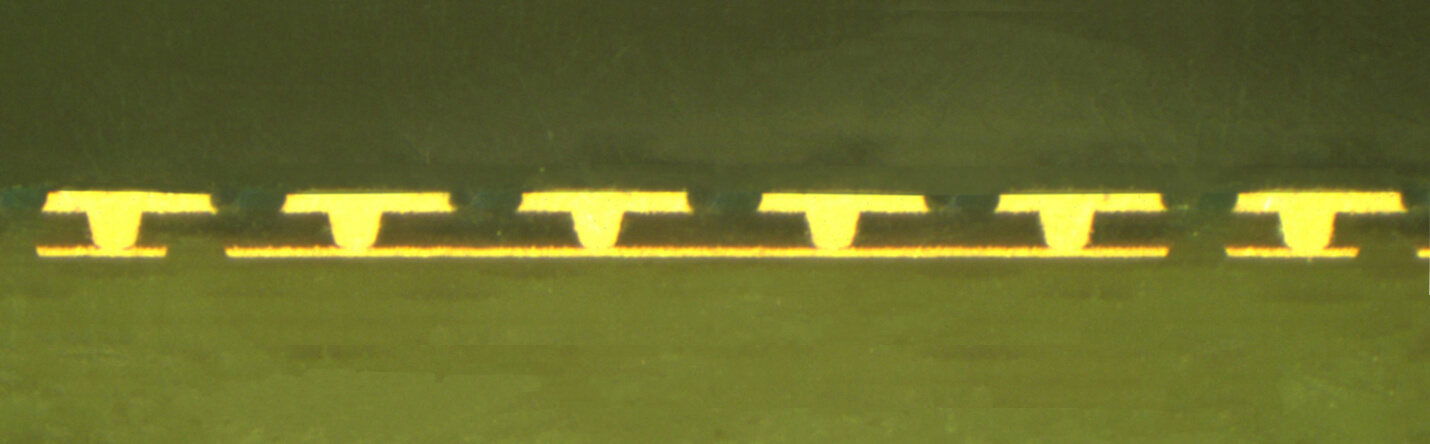

Copper filled blind vias Cross Section of Copper Filled Vias

Cross Section of Copper Filled Vias