GSPK offer a range of PCB tools to aid assembly

Aluminium Support Tools

Our precision-engineered aluminium support tools are designed to solve persistent challenges in PCB assembly. They aid processes such as stencil printing and component placement, helping alleviate issues like board warping, flexing, and uneven thermal distribution to enhance production consistency and yield.

Their anodised aluminium construction ensures durability and performance longevity, even under the stresses of demanding production cycles, helping achieve greater operational reliability and cost efficiency.

Specifications:

PCB carriers

PCB carriers are used to hold and transport PCBs during various manufacturing processes such as assembly, inspection or soldering. They ensure safe transition of the PCBs through the production line.

Increased Stencil life:Our design minimizes stencil wear, reducing maintenance needs and downtime, which extends the stencil's operating life, saving both time and costs for the user.

Improve print quality:Our carriers ensure precise alignment and consistent board flatness during solder paste application, enabling even paste deposition across all pads. This reduces misprints and defects, delivering high-quality, reliable prints while minimizing rework, maximizing yield, and lowering production costs.

Avoid Short Circuits:Our products design prevents solder paste residue from spreading to unintended areas, reducing the risks of electrical shorts and contamination. This enhances the reliability and safety of the final assembly, minimising costly defects and improving overall product quality.

Specifications:

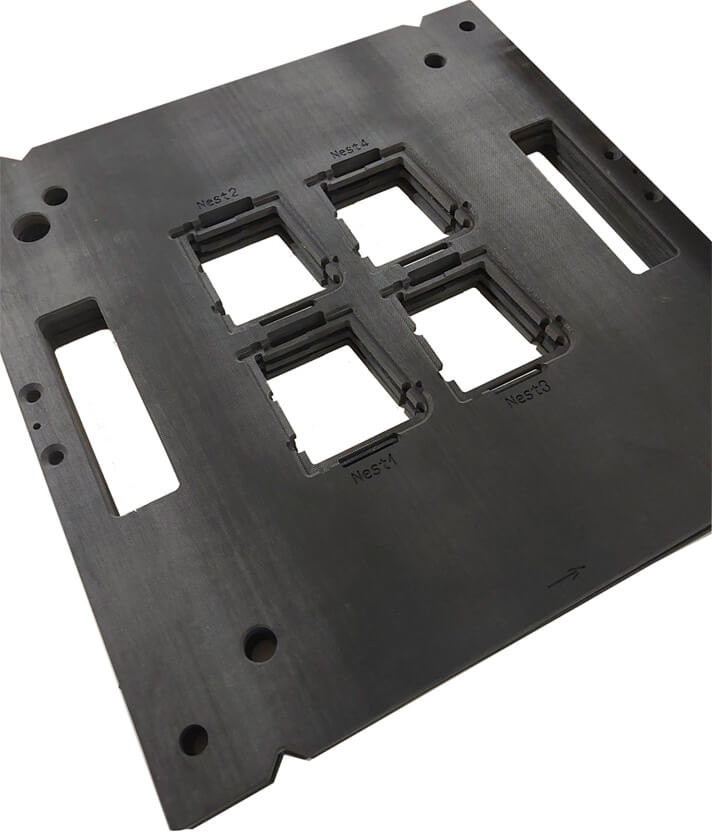

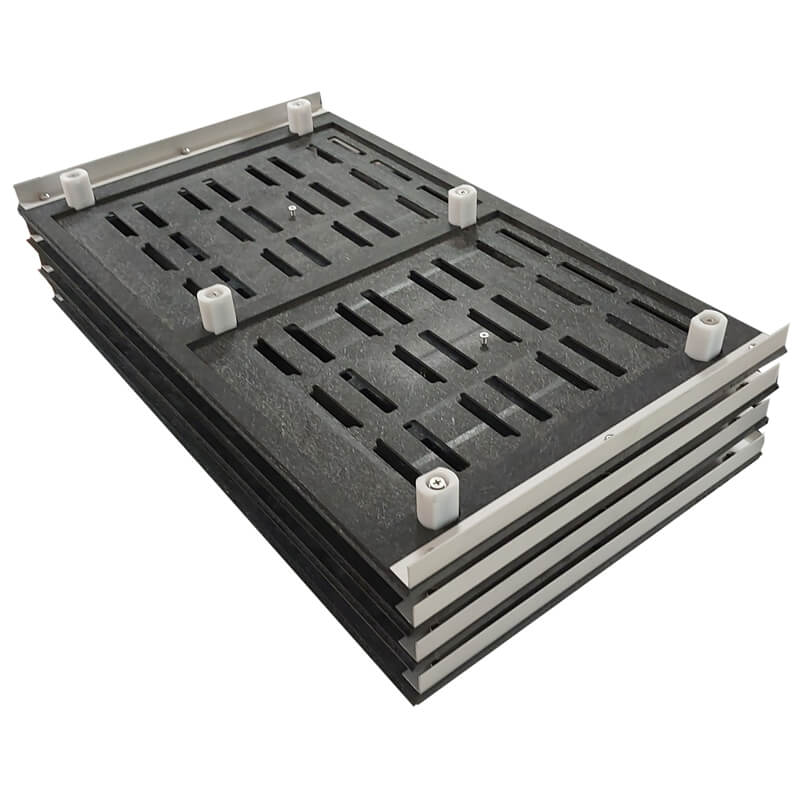

PCB Wave Solder Pallets

Wave Soldering Pallets

Wave soldering pallets play a vital role in streamlining the PCB assembly process. These pallets are designed to enhance production efficiency by improving throughput, securely positioning critical components, and facilitating the soldering of through-hole components in assemblies.

Wave soldering pallets also provide precise masking for bottom-side components that should not be soldered. This ensures only the intended areas are exposed to the solder wave, while the pallet safely transports the entire board through each stage of the process.

Specifications: